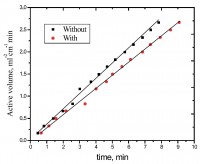

The reduction process of nitrate at copper based electrodes was investigated. The cyclic voltammetry (CV) studies allowed us to establish the specific parameters concerning the electrodeposition of the individual metals and their alloys. It was demonstrated that the products resulting from electrochemical nitrate reduction (ENR) in alkaline media can be detected by cyclic hydrodynamic voltammetry (CHV) and square wave voltammetry (SWV) techniques at Cu and CuSn plated Pt electrodes. Moreover, using SWV ammonium can be electrochemically detected with good accuracy. An enhancement of the electrocatalytic activity of Cu by alloying it with Sn was observed. The reduction of nitrate was investigated in an engineering laboratory scale flow reactor under different operating conditions. On the two investigated types of cathode materials (Cu and CuSn), the concentration of nitrate was reduced electrochemically to the maximum permissible limit (50 mg/L) with a energy consumption in the range of 2 – 16 kWh/kg NaNO3 at a CuSn cathode.