Advanced Features of Electrolytic Silver-tin (AgSn20) Process

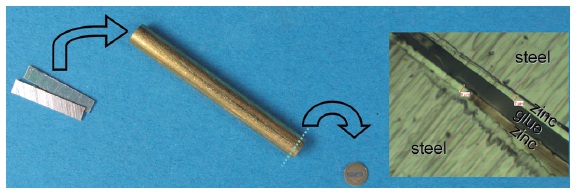

This work describes the Silveron™ GT-820 Silver-Tin as a robust process for the electrodeposition of silver-tin alloys of composition equal to Ag3Sn and Ag4Sn. A design of experiment method was used to study the influence of process parameters on the deposit performance. It was found that the alloy composition is controlled by organics components of the bath. It is independent on the metal concentration ratio and the applied current density inside the specified process window. The silver-tin deposit is semi-crystalline directly after plating but can be converted to a fully crystalline material by a short annealing. This coating is not only ductile and tarnish resistant but also displays a good insertion and retention force needed for press-fit interconnections. The product was tested successfully under serial production conditions and shown to be suitable for tin and tin-lead replacement in solderless interconnections.