Hybridisation as an efficient joining, electrochemical corrosion study as a need

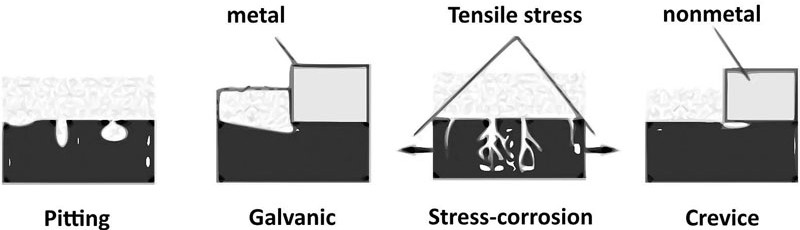

The composite technology allows the development of structures with a high degree of integration, where the number of elements and auxiliary means for their structural joining are minimised. This can only be achieved by the use of appropriate manufacturing and design processes. Some advantages of such an efficient integration would be the low installation and inspection efforts, shorter cycle times in the production, higher robustness and lower manufacturing costs. Despite this high potential, joining these highly integrated parts is indispensable because of restrictions concerning the components’ complexity, repair requirements as well as material specific limitations [1].