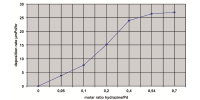

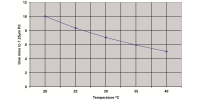

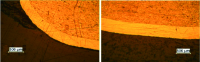

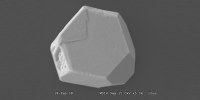

Electrodeposition has recently been shown to successfully create three dimensional micro- or nanostructures. Here we demonstrate that highly faceted metallic architectures are readily achieved by appropriate electrodeposition conditions. Three dimensional silver and copper mes-ocrystals with different shapes and size are potentiostatically electrodeposited on highly oriented pyrolytic graphite (HOPG) from simple sulfate and nitrate baths, respectively. The electrodeposition potential plays the most important role in determining the shape and size of mesocrystals. For silver mesocrystals, individual crystals with a range of shapes and sizes are observed which are not influenced by steps in the HOPG substrate. However, when copper is electrodeposited at one distinct potential it tends to form either wires on step edges or particles on terraces. Upon application of a dual pulse potential technique, well defined highly faceted copper mesocrystals are produced.