In this paper the influence of a mid-phosphorous electroless nickel coating on EN-AW 2618A was studied. Special emphasis was put on the metalturn-over (MTO) and a heat treatment on the coating properties and their influence on the fatigue properties. The increasing MTO leads to an increase in phosphorous content resulting in a reduction of hardness, while the ductility is much less affected. The low temperature heat treatment increases the hardness through a crystal growth. The fatigue tests show, that the electroless nickel coating can both have a positive as well as a negative influence on the fatigue properties. At higher mechanical stresses the deposit tends to reduce the lifetime, while at lower loads the lifetime gets increased. The reduction of lifetime is caused by defects in the coating which act as stress concentrators. An increase in MTO leads to a higher amount of coating defects and therefore a higher possibility for a reduction of the lifetime. Further research has to focus on the growth mechanisms of those defects since their influence seems to be more significant than other factors like the phosphorous content.

1 Introduction

High strength aluminium alloys are broadly used in the automotive and aviation industry. As an example the wrought aluminium alloy EN AW 2618A is used for pistons [1] or compressor wheels of automotive turbochargers [2].

The lifetime properties of compressor wheels can be restricted due to corrosion and erosion [3]. Aggressive environments (e.g. sea water, high humidity, exhaust gases from the exhaust gas recirculation) can lead to corrosion. Furthermore dust and other particles can lead to erosion of the compressor blades. All the effects lower the efficiency and can cause failure of the compressor. Moreira reported the fracture of a compressor blade due to corrosion [4]. Therefore some compressor wheels require a coating to prevent damage and to ensure constant efficiency. Electroless nickel is a suitable coating for such applications [3].

An electroless nickel coating increases the resistance to corrosion and erosion but can have a critical influence on the fatigue properties. The fatigue properties are very important for compressor wheels since they are exposed to high centrifugal forces. There are many researches on the influence of electroless nickel coatings on the fatigue properties of steels [5–7] while the

influence on aluminium alloys has been studied less. As reported by Lonyuk et al. high-phosphorus coatings on EN AW-2618A can increase the fatigue properties [8]. Other authors also report a positive influence of a high-phosphorous coating on the fatigue properties of a 7075 alloy [9]. There are also some results that show almost no influence of the coating on the properties [10]. Therefore one aspect of the present paper is the influence of a mid-phosphorous electroless coating on the fatigue properties of EN AW-2618A. Another important factor is the bath age of the used electroless nickel electrolyte since it can lead to a change in the coating properties [11] and is an important economical factor. Also there is little knowledge about the influence of the MTO on the fatigue properties. Since compressor wheels are heated by the compression of the air [4], the influence of a heat treatment on the coating and the fatigue properties are also investigated.

2 Experimental

2.1 Material and coatings

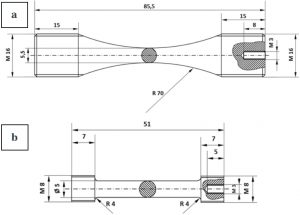

The substrate material used for all further testings is the wrought aluminium alloy EN AW-2618A (AlCu2Mg1.5FeNi). The substrate material in the condition T6511 was supplied in extruded bars from the same cast with a diameter of 48 mm. The measured composition by OES was 2.49% Cu, 1.52% Mg, 1.51% Fe and 1.05% Mg. The bars were machined into the sample geometries shown in Figure 1. Afterwards samples were plated in an industrial electroless nickel process, including an activation by double zincate etching. After the zincate etching a commercial electroless nickel coating with a coating thickness of 25-30 μm was applied. The coating usually contains between 6-9 % phosphorus and up to 3% antimony (stabilizer). The chemical composition of the coating was determined by GD-OES (Spectruma GDA 750 HR).

Fig. 1: Sample geometries used for (a) fatigue tests and (b) tensile tests, the coating thickness was 25 to 30 μm

To investigate the influence of the bath age, three different MTOs where used for all further tests. The first one was MTO 0, which correlates to a completely fresh bath. The other two are MTO 2 and MTO 3.5. The increase of MTO was carried out by plating the same substrate material for the needed duration. To simulate the heating of the compressor wheel, a heat treatment was performed (200 °C for 1000 hours).

2.2 Characterization of the substrate material and the coatings

2.2.1 Coating structure

The structure of the as deposited coatings was analysed by a metallographic cross section. The samples were carefully cut to prevent decohesion of the coating from the substrate, since decohesion of the coating tends to occur at to high cutting speeds. The extracted cross section (20 mm) was hot embedded in a graphite containing resin, to enable conductivity for the SEM analysis. After that the samples were grinded, polished and etched for 4 minutes with an etching solution containing 50 % concentrated nitric acid and 50 % acetic acid. After the etching the samples were

rinsed with tap water, followed by an ultrasonic cleaning in water and in isopropanol. The cross sections were analysed in a Zeiss Supra® 40VP FESEM using an acceleration voltage of 5 kV and the In-lens secondary electron detector.

2.2.2 Hardness and indentation modulus

For the substrate material the Brinell hardness (HB 2.5/62.5) was measured using a Struers DuraVision® 20.

The hardness and the indentation modulus of the as deposited and the heat treated coatings were determined by nanoindentation using a Fischerscope H100. Before the indentation the surface of the samples was polished with 1 μm SiC-particles to reduce the roughness. For each condition 15 indentations with a load of 250 mN were carried out (hardness values referred as HV 0,025 in the result section).

2.2.3 X-Ray diffraction

X-Ray diffraction, using a Seifert XRD 3000®, was carried out to determine the internal stress in the substrate material as well as to analyse the as deposited and the heat treated condition of the coatings. For the analysis Cr-Kα radiation was used. The 2θ angle was varied between 50 and 150°, with a step size of 0.1° and a measuring time of 5 seconds for each step.

2.2.4 Tensile tests

Tensile tests were used to determine the ductility of the coatings in the as deposited and the heat treated condition. During the tensile test with a Zwick® 250 the elongation speed had a constant value of 0.004 1/min. For each coating condition 5

samples were tested. In the tensile tests both the stress as well as the elongation speed were monitored over the strain. The first crack of the coating produced a clearly noticeable sound, as well as a slight decrease in the stress and a large peak in the elongation speed (Fig. 2). The strain of the sample, where the first crack of the coating occurred, was then taken as the elongation at fracture of the coating.

Fig. 2: Diagram of the tensile test of a coated sample, the black arrow indicates a crack in the coating with a noticeable sound at the same time. The first crack was taken as the elongation at fracture

2.3 Fatigue testing

For the fatigue testing uncoated samples in the heat treated and as received condition were tested as a reference to determine the influence of the coating on the fatigue properties. The tests were done both for the as deposited condition as well as for the heat treated condition. For the tensile-tensile fatigue tests with a frequency of 165 Hz a constant value of the minimal force of 50 N was chosen, the maximal force was varied between 5650 and 8850 N. For the S-N-curves the force was converted into stress and the total number of cycles to failure where taken. The fatigue strength was determined at 107 cycles. After the fatigue testing the fracture surfaces of all samples were analysed by SEM, using the secondary electron detector.

3 Results and discussion

3.1 Influence of the heat treatment on the substrate material

The substrate material in the T6511 condition has a Brinell hardness of 151 ± 1 HB 2.5/62.5. As reported in [1] the peak age condition T6 is reached after a heat treatment at 200 °C for 20 to 25 hours, resulting in a Brinell hardness of 142 HB 2.5/62.5. Thus, the used T6511 condition has slightly higher mechanical properties. The heat treatment of 200 °C for 1000 hours leads to an over-aging resulting in a lower hardness of 124 ± 1 HB 2.5/62.5. The over-aging causes a growth of the Al‑Cu‑precipitations, especially at the grain boundaries.

The second effect of the heat treatment is the

reduction of internal stress at the specimen surface. Due to the machining the T6511 condition shows compressive stresses of around ‑60 MPa. The heat treatment reduces the compressive stresses to around ‑15 MPa.

3.2 Characterization of the coatings

Table 1 shows the chemical composition of the coatings at the different MTOs. An increase in MTO leads to an increase in the phosphorous content from 6.3 % to almost 9.5 % of the coating, in accordance with [12]. Furthermore with increasing MTO the antimony content in the coating is reduced. The following reactions shows the precipitation of nickel and phosphorous in the electroless nickel coating process

[13–15]:

<1>: NiSO4 + 3 NaH2PO2 + 3 H2O → Ni + 3 NaH2PO3 + 2 H2 + H2SO4

<2>: 3 NaH2PO2 → 2 P + NaH2PO3 + 2 NaOH + H2O

With increasing MTO the concentration of sodium orthophosphate in the bath increases, reducing the reaction rate of <1>. Therefore coatings with higher MTO contain more phosphorous and less nickel.

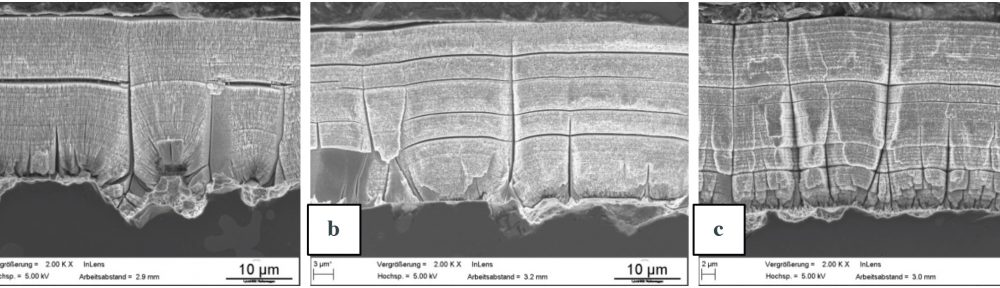

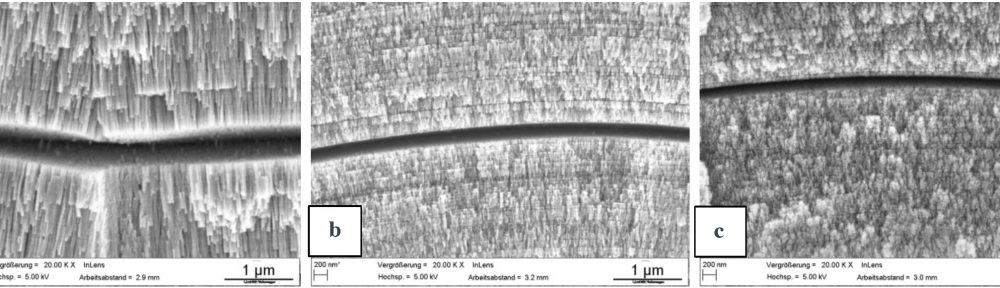

The etched cross sections (Fig. 3, 4) show, that the MTO 0 has both a columnar structure as well as a lamellar structure. With higher MTO the lamellar structure becomes more evident, while the distance between the lamellae seems to decrease with increasing MTO. Each lamella in the etched cross section has a different phosphorous content, so lamellae with lower phosphorous content are stronger etched than those with higher contents. The reason for the lamellar structure comes from the diffusion in the coating process. Through local changes in the electrolyte concentration, especially the pH-value, the coating is precipitated with varying phosphorous contents [16,17]. With an increase in MTO the coating rate is reduced [12]. Therefore the diffusion has more time to compensate the varying pH-values, resulting in a more homogeneous coating structure.

Fig. 3: Etched cross section of the coatings in the as deposited condition of (a) MTO 0, (b) MTO 2, (c) MTO 3.5; the substrate material is in the lower part of the picture. The coatings show the lamellar structure as well as some defects reaching from the substrate to the surface

Fig. 4: Detail of the etched cross section of the coatings in the as deposited condition of (a) MTO 0, (b) MTO 2, (c) MTO 3.5; the columnar and lamellar structure can be seen. Both structures get less evident with increasing MTO

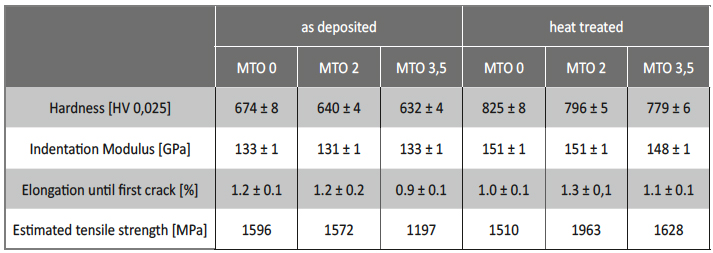

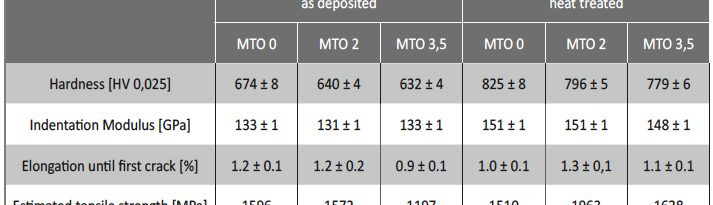

With increasing MTO the hardness of the as deposited coating decreases (Tab. 2) while the indentation modulus seems to be constant. The increasing phosphorous content explains the decreasing hardness, since lower phosphorous coatings tend to have a higher Vickers hardness [18] due to the higher content of nano-crystalline phase in the amorphous matrix [19]. A heat treatment of 200 °C for 1000 hours leads to an increase in Vickers hardness of about 150 HV 0,025, while the influence of MTO is still evident. The heat treatment also leads to an increase of the indentation modulus. Keong et al. also reported that the increase in hardness after low temperature heat treatment depends on the phosphorous content, leading to lower hardness with higher phosphorous contents [20].

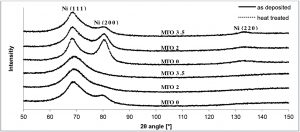

The XRD patterns (Fig. 5) indicate that there are different crystallographic orientations in the as Figure 3: Etched cross section of the coatings in the as deposited condition of (a) MTO 0, (b) MTO 2, (c) MTO 3.5; the substrate material is in the lower part of the picture. The coatings show the lamellar structure as well as some defects reaching from the substrate to the surface Fig. 4: Detail of the etched cross section of the coatings in the as deposited condition of (a) MTO 0, (b) MTO 2, (c) MTO 3.5; the columnar and lamellar structure can be seen. Both structures get less evident with increasing MTO deposited coatings. According to [21–23] the first peak corresponds to the {111} nickel orientation and the second peak to the {200} orientation. With increasing MTO the intensity of the {200} peak decreases while the columnar structure of the coatings (Fig. 4) also gets less evident. Therefore the XRD-measurements can be seen as an indicator for the grain size of the columns. If the columns are broader (MTO 0) other crystallographic orientations like {200} can also be detected. In addition to that the crystal growth during the coating process seems to prefer the {111} orientation. The heat treatment of electroless nickel coatings at 200°C leads to the reduction of internal stress, short range diffusion processes and the precipitation of metastable crystalline phases [24–26]. The increasing intensity of the {200} orientation indicates the crystal growth inside the columns. In addition to that, the {220} orientation of nickel can also be found after the heat treatment.

Fig. 5: XRD patterns for the as deposited and the heat treated condition, the corresponding crystallographic orientations are marked. In the as deposited condition the {200} peak gets less evident with increasing MTO, the heat treatment leads to a higher intensity of {200} as well as the formation of the {220} peak

The MTO has no big influence on the elongation until the occurring of the first crack in the coating (Tab. 2). Though it can be seen, that MTO 3.5 has a slightly lower elongation. This results from poor adhesion since delamination during the tensile test took place at MTO 3.5. The heat treated condition of MTO 3.5 has a higher elongation and no delamination took place. A heat treatment at 180 to 200 °C is often used as an adhesion tempering.

Linka et al. reported, that there is an influence of MTO on the ductility [12] but only at MTO higher than 6 which have not been studied in this paper. However the indentation modus changes after the heat treatment. Since the indentation modulus shows good correlation with the Young’s modulus the tensile strength of the coatings can be estimated under the assumption of linear-elastic failure during the tensile test [27]. This shows a significant increase of the tensile strength after the heat treatment.

3.3 Fatigue properties

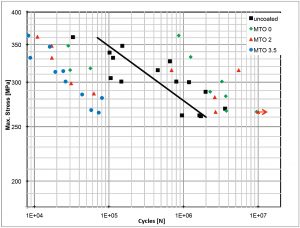

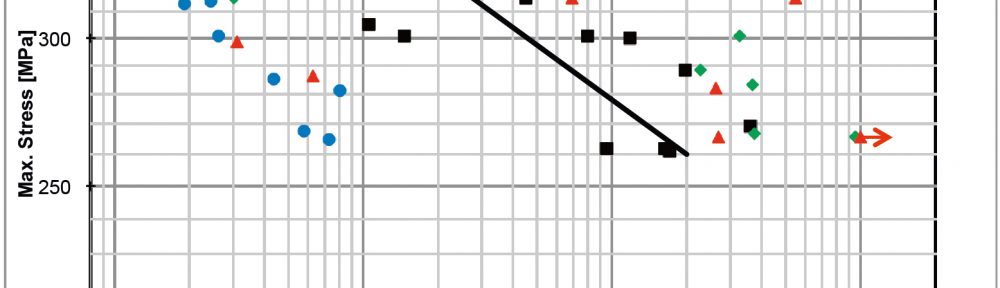

3.3.1 Without heat treatment

The S-N-curves (Fig. 6) for the uncoated condition show a steady increase of the numbers of cycles to failure with decreasing stresses. The fracture surfaces of the uncoated T6511 condition show a sub-surface crack initiation, as reported in [8]. High strength aluminium alloys often tend to have sub-surface crack initiations sites if the grain boundaries or the intermetallic precipitations function as a stress concentrator [28,29]. In addition to that, the samples have compressive stresses at the surface.

Fig. 6: Cycles to failure as a function of the maximum stress for the uncoated (the line indicates the 50% failure rate) and the

coated conditions without heat treatment. The coated samples show either a positive or a negative influence on the fatigue

properties. The increase in MTO leads to a higher chance for a negative influence

The coated samples in the as deposited condition show two different areas in the S-N-diagram. At high maximum stresses the coating tends to have a strong negative influence on the fatigue properties whereas lower loads show a positive influence on the fatigue properties. With increasing MTO the possibility of the negative influence seems to increase, resulting in a higher number of samples with decreased lifetime. In addition to that, the increasing MTO also influences the maximum stress where the mechanism shifts from a negative to a positive influence on the fatigue properties. MTO 0 has a positive influence on the fatigue properties at maximum stresses lower than 315 MPa whereas MTO 2 shows a positive influence at stresses

lower than 285 MPa.

All samples with lower cycles to failure as the uncoated samples show the crack initiation site in the coating, while the other samples show crack initiation sites in the substrate material. Lonyuk et al. have shown a similar behaviour of the crack initiation site under alternating loads, while there was no influence on the numbers of cycles to failure [8].

Figure 8 shows the crack initiation sites for the first mechanism. All samples with a reduction of the lifetime show the crack initiation in the coating, located at a defect in the coating. These defects show different morphologies, while the defects of Figure 8c occur only at MTO 3.5. The defects of Figure 8a and 8b seem to be defects due to contamination of the bath while those of Figure 8c seem to come from a failure in the growth of the coating itself. This failure might be caused due to higher amounts of reaction products from the coating process in the coating bath with increasing MTO. The fatigue crack propagates from the defect into the coating which can be seen at the fatigue striations in the coating. After a short time the high stresses at the crack tip lead to ductile failure of the coating and the further propagation of the fatigue crack into the substrate material.

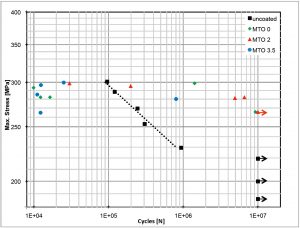

Fig. 7: Cycles to failure as a function of the maximum stress for the uncoated (the line indicates the 50% failure rate) and the

coated conditions with heat treatment.

The results are comparable to the as deposited condition

Fig. 8: Fracture surface of three different samples in the as deposited condition with a negative influence on the fatigue properties,

showing the crack initiation in the coating for: (a) MTO 0 with 315 MPa maximum stress, (b) MTO 2 with 360 MPa and (c) MTO 3.5 with 330 MPa. The coating defects of (c) tend to occur only at higher MTOs

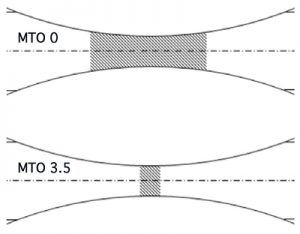

Samples with MTO 0 show crack initiations outside of the region of the smallest diameter (Fig. 9), this region also correlates to the highest stresses. Thus the defects function as a stress concentrator or have a locally lowered fatigue strength. With an increase in MTO the crack initiation occurs more likely in the region of the smallest diameter of the samples. Therefore the amount of defects has to increase with increasing MTO, resulting in a higher probability for a coating defect in the region of the smallest sample diameter.

Fig. 9: Schematically drawing of the fatigue samples, the hatching indicates the regions for the crack initiation of MTO 0 and 3.5

For the samples with increased lifetime the crack initiation is similar to the uncoated T6511 condition in the substrate material. Figure 10 shows the crack initiation with flat surfaces and the propagation of the fatigue crack from the substrate material into the coating. After the fatigue crack has reached the coating a small fatigue crack from the substrate material into the coating emerges. After that the coatings shows ductile failure due to the high stresses at the crack tip. Since the coating has a higher toughness then the substrate material, it has a strengthening effect if the crack initiation is not in the coating.

Fig. 10: Fracture surface of a samples with increased lifetime coated with MTO 0 in the as deposited condition, tested at 285 MPa maximum stress: (a) crack initiation in the substrate material with flat areas and (b) propagation of the fatigue crack from the substrate material into the coating

3.3.2 After heat treatment

As the mechanical properties of the T6511 condition decrease due to over-aging the heat treated uncoated samples have a lower fatigue strength (Fig. 7). In addition to that, the crack initiation shifts from a sub-surface area to the specimen surface. The over-aging leads to a growth of the Al‑Cu‑precipitations at the grain boundaries, enhancing their fatigue strength, and lowers the compressive stresses at the specimen surface. Both explain the shift of the crack initiation from a sub-surface area to the specimen surface.

The coated samples show the same two regions as in the as deposited condition. The coating decreases or increases the fatigue properties of the substrate material. The effect depends on the crack initiation in the coating or in the substrate material.

Thus, the samples with an increased lifetime show comparable results to the as deposited condition. The toughness increase of the coating negotiates the fatigue strength loss of the substrate material. However, if the crack initiation starts in the coating, the reduction of lifetime is comparable to the reduction of lifetime in the as deposited condition.

3.3.3 Comparison to other references

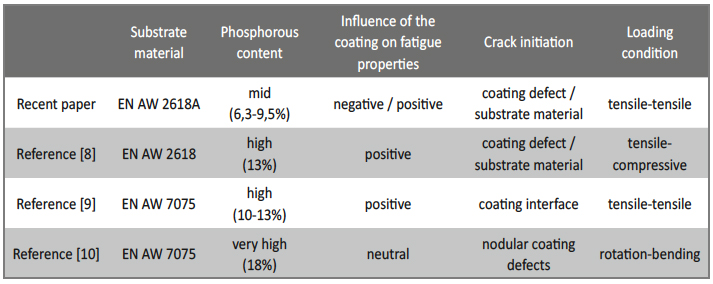

The results of the recent paper show both a negative as well as a positive effect of the electroless nickel coating on the fatigue properties. Other references report either a positive or a neutral influence (Tab. 3).

Lonyuk et al. [8] coated the same substrate material with a high phosphorous electroless nickel coating. The crack initiation mechanism is in good accordance to the recent paper. The crack initiates either at a coating defect or in the substrate material. In contrast to the shown results they report a positive influence on the fatigue properties, even if the crack initiates in the coating. This could be an effect of the high phosphorous electroless nickel coating and the higher ductility of those coatings, resulting in a higher resistance to crack propagation. In [10] Puchi-Cabrera et al. report the crack initiation from coating defect without a negative influence on the fatigue properties. This supports the influence of the phosphorous content on the fatigue properties.

In contrast to both mentioned references Rahmat et al. [9] report a positive influence on the fatigue properties but show the crack initiation from the coating interface. This could be an indicator for poor adhesion of the tested coatings or an influence of the testing conditions.

Summarizing the results, the effect of the phosphorous content on the fatigue properties has to be further investigated. High phosphorous coatings tend to have a positive influence on the fatigue properties even if the crack initiation happens

in the coating. Thus, the results of this paper show, that the phosphorous contend has is a minor factor compared to the MTO. In this paper MTO 3.5 coatings have the highest phosphorous content (9.5 %) but show the worst influence on the fatigue properties due to their high density of coating defects. This indicates that the MTO is a more critical factor then the phosphorous content.

4 Conclusion

The present study was focused on the influence of MTO on the coating properties and the influence on the fatigue properties of a mid-phosphorus electroless nickel coating on the aluminium alloy EN AW-2618A.

- The main influence of MTO on the coating properties is an increase in the phosphorous content with increasing MTO. Due to the increase in phosphorous content other coating properties such as hardness decrease.

- The heat treatment of electroless nickel coatings of 200 °C for 1000 hours leads to an increase in hardness due to the crystal growth of nickel while the hardness increase has no influence on the elasticity.

- The coating has a positive influence on the fatigue properties of EN AW-2618A if the crack initiation starts in the substrate material. Due to defects in the coating the crack initiation can also start in the coating resulting in a decrease of the fatigue properties.

- The main influence of MTO on the fatigue properties is the amount of defects in the coating. This leads to a higher amount of samples with decreased lifetime.

- After a heat treatment the samples with increased lifetime show no loss in the fatigue strength, while the effect on samples with decreased lifetime is comparable to the as deposited condition.

- The comparison to other references shows an influence of the phosphorous content on the fatigue properties of electroless nickel coatings, resulting in better fatigue resistance of high phosphorous coatings. Thus mentioned, the MTO is a more critical factor.

Acknowledgements

The authors acknowledge Bosch Mahle Turbo Systems GmbH & Co. KG for supplying the raw material. Furthermore the authors would like to acknowledge AHC Oberflächentechnik GmbH for supplying the coatings.

References

- L. Ceschini, A. Morri, A. Morri, M. Di Sabatino, Effect of thermal exposure on the residual hardness and tensile properties of the EN AW-2618A piston alloy, Materials Science and Engineering: A 639 (2015) 288–297.

- BorgWarner Turbo Systems, TurboNews (2015) 12–13.

- S. Münz, P. Schmidt, C. Römuss, K.-H. Brune, H.-P. Schiffer, Turbolader für Emissionskonzepte mit niederdruckseitiger Abgasrückführung, BorgWarner – Knowledge Libary (2007).

- M.F. Moreira, Failure analysis in aluminium turbocharger wheels, Engineering Failure Analysis 61 (2016) 108–118.

- Y. Garcés, H. Sánchez, J. Berrıó s, A. Pertuz, J. Chitty, H. Hintermann, E.S. Puchi, Fatigue behavior of a quenched and tempered AISI 4340 steel coated with an electroless Ni-P deposit, Thin Solid Films 355-356 (1999) 487–493.

- A. Pertuz, J. Berrıó s, E. Puchi Cabrera, Influence of a commercial electroless Ni–P deposit on the fatigue properties of a notched and unnotched SAE 4140 steel, Surface and Coatings Technology 133-134 (2000) 572–582.

- E.S. Puchi, M.H. Staia, H. Hintermann, A. Pertuz, J. Chitty, Influence of Ni-P electroless coating on the fatigue behavior of plain carbon steels, Thin Solid Films 290-291 (1996) 370–375.

- B. Lonyuk, I. Apachitei, J. Duszczyk, Effect of high-phosphorus electroless nickel coating on fatigue life of Al–Cu–Mg–Fe–Ni alloy, Scripta Materialia 57 (2007) 783–786.

- M.A. Rahmat, R.H. Oskouei, R.N. Ibrahim, R.K. Singh Raman, The effect of electroless Ni–P coatings on the fatigue life of Al 7075-T6 fastener holes with symmetrical slits, International Journal of Fatigue 52 (2013) 30–38.

- E. PUCHI-CABRERA, C. VILLALOBOSGUTIERREZ, I. IRAUSQUIN, J. LABARBERASOSA, G. MESMACQUE, Fatigue behavior of a 7075-T6 aluminum alloy coated with an electroless Ni–P deposit, International Journal of Fatigue 28 (2006) 1854–1866.

- Z. Chen, X. Xu, C.C. Wong, S. Mhaisalkar, Effect of plating parameters on the intrinsic stress in electroless nickel plating, Surface and Coatings Technology 167 (2003) 170–176.

- G. Linka, W. Riedel, Korrosionsbestaendigkeit von chemisch- reduktiv abgeschiedenen Nickel-Phosphor-Legierungsueberzuegen als Funktion des Badalters, Galvanotechnik 77 (1986) 568–573.

- L.M. Abrantes, On the Mechanism of Electroless Ni-P Plating, J. Electrochem. Soc. 141 (1994) 2356.

- B.D. Barker, Electroless deposition of metals, Surface Technology 12 (1981) 77–88.

- D.W. Baudrand, Electroless Nickel Plating, ASM Handbook Volume 5 Surface Engineering (1994) 290–310.

- H.-G. Schenzel, Mikrostruktur und Korrosionsverhalten von chemisch abgeschiedenen Nickel-Phosphor-Schichten, VDIVerlag GmbH, Düsseldorf, 1990.

- H.H. Urlberger, Über einige praxisrelevante Eigenschaften außenstromlos abgeschiedener Nickel-Phosphor-Überzüge in Abhängigkeit vom Alter der Elektrolytlösung, Dissertation Technische Hochschule Darmstadt, 1995.

- I. Apachitei, Synthesis and Characterisation of Autocatalytic Nickel Composite Coatings on Aluminium, JB&A Grafische Communicatie, Wateringen, 2001.

- R.N. Duncan, The Metallurgical Structure of Electroless Nickel Deposits: Effect on Coating Properties, Plating and surface finishing 83 (1996) 65–69.

- K.G. Keong, W. Sha, S. Malinov, Hardness evolution of electroless nickel–phosphorus deposits with thermal processing, Surface and Coatings Technology 168 (2003) 263–274.

- Z. Guo, K.G. Keong, W. Sha, Crystallisation and phase transformation behaviour of electroless nickel phosphorus platings during continuous heating, Journal of Alloys and Compounds 358 (2003) 112–119.

- K.G. Keong, W. Sha, S. Malinov, Crystallisation kinetics and phase transformation behaviour of electroless nickel–phosphorus deposits with high phosphorus content, Journal of Alloys and Compounds 334 (2002) 192–199.

- K.G. Keong, W. Sha, S. Malinov, Crystallization and phase transformation behaviour of electroless nickel-phosphorus deposits with low and medium phosphorus contents under continuous heating, JOURNAL OF MATERIALS SCIENCE 37 (2002) 4445–4450.

- M. Erming, L. Shoufu, L. Pengxing, A transmission electron microscopy study on the crystallization of amorphous Ni-P electroless deposited coatings, Thin Solid Films 166 (1988) 273–280.

- N.M. Martyak, K. Drake, Peak-profile analysis of electroless nickel coatings, Journal of Alloys and Compounds 312 (2000) 30–40.

- S.H. Park, D.N. Lee, A study on the microstructure and phase transformation of electroless nickel deposits, J Mater Sci 23 (1988) 1643–1654.

- H.A. Jehn, Galvanische Schichten: Abscheidung, Eigenschaften,

Anwendungen, Meßmethoden, Qualitätssicherung, Expert-Verl. [u.a.], Ehningen bei Böblingen u.a., 1993. - H. Weiland, J. Nardiello, S. Zaefferer, S. Cheong, J. Papazian, D. Raabe, Microstructural aspects of crack nucleation during cyclic loading of AA7075-T651, Engineering Fracture Mechanics 76 (2009) 709–714.

- O. Khalil, Isothermes Kurzzeitermüdungsverhalten der hoch-warmfesten Aluminium-Knetlegierung 2618A (AlCu2Mg1,5Ni), KIT Scientific Publishing, 2014.

PDF Version of the article |

Flash Version of the article |

|

| [qrcode] | ||

![Tab. 1: Chemical composition of the coatings measured by GD-OES in [Mass-%]](https://www.jept.de/wp-content/uploads/2018/01/tab1.jpg)