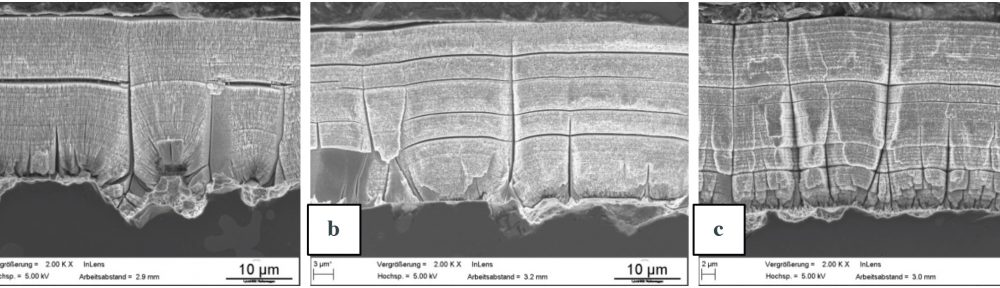

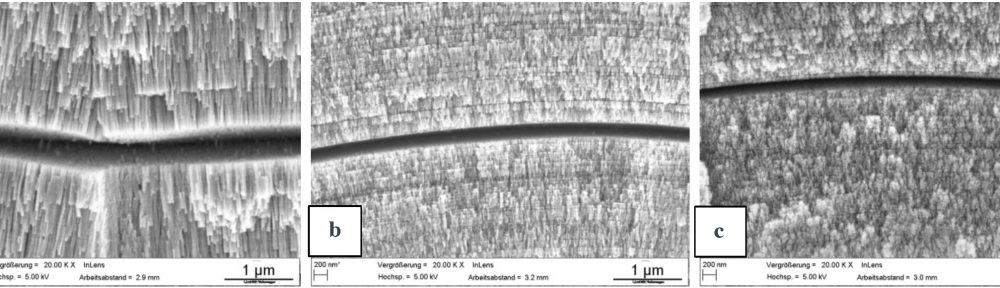

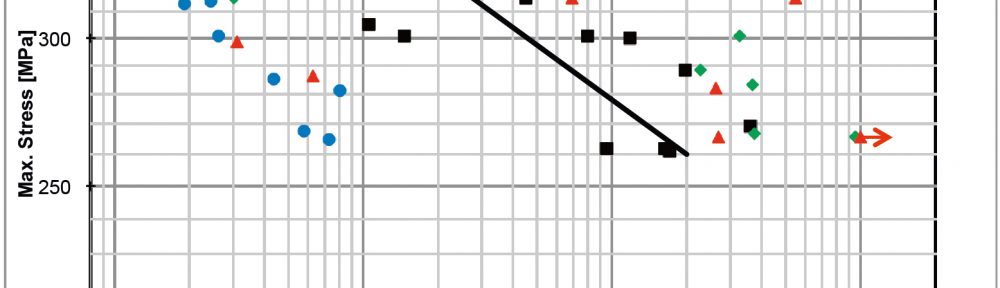

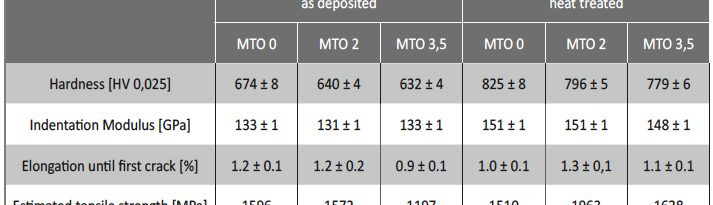

In this paper the influence of a mid-phosphorous electroless nickel coating on EN-AW 2618A was studied. Special emphasis was put on the metalturn-over (MTO) and a heat treatment on the coating properties and their influence on the fatigue properties. The increasing MTO leads to an increase in phosphorous content resulting in a reduction of hardness, while the ductility is much less affected. The low temperature heat treatment increases the hardness through a crystal growth. The fatigue tests show, that the electroless nickel coating can both have a positive as well as a negative influence on the fatigue properties. At higher mechanical stresses the deposit tends to reduce the lifetime, while at lower loads the lifetime gets increased. The reduction of lifetime is caused by defects in the coating which act as stress concentrators. An increase in MTO leads to a higher amount of coating defects and therefore a higher possibility for a reduction of the lifetime. Further research has to focus on the growth mechanisms of those defects since their influence seems to be more significant than other factors like the phosphorous content.

JEPT – Journal for Electrochemistry and Plating Technology

Edited by: DGO-Fachausschuss Forschung – Hilden / Germany