Environmentally friendly electrolyte for the electrodeposition of Cu-Zn alloys

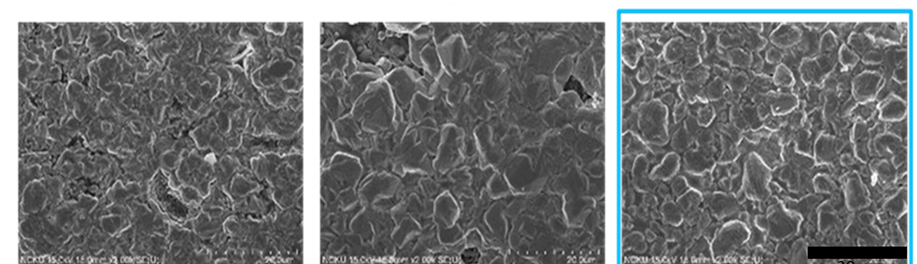

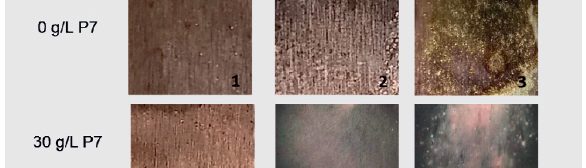

In this work, cathodic polarization experiments on a rotating disk electrode in both static and rotating conditions were carried out using the novel electrolyte with and without the addition of a polymeric cationic surfactant (Polyquaternium-7). The deposits were later dissolved by anodic stripping to characterize the electrochemical processes involved in the Cu-Zn-Glutamate system. Galvanostatic experiments, using flat steel electrodes as substrate, were carried out at different current densities with and without additive. These coatings were characterised by SEM, EDS and XRD.

Cu-Zn alloys with compositions between 37-83 wt.% of copper were obtained. α, β and γ phases were obtained depending on the electrolyte composition and the applied current density.

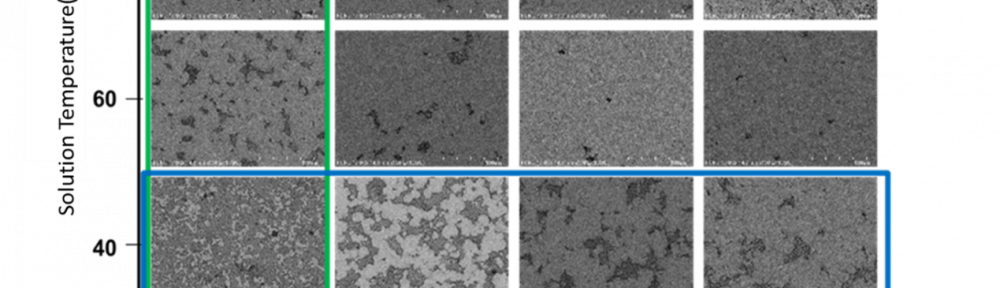

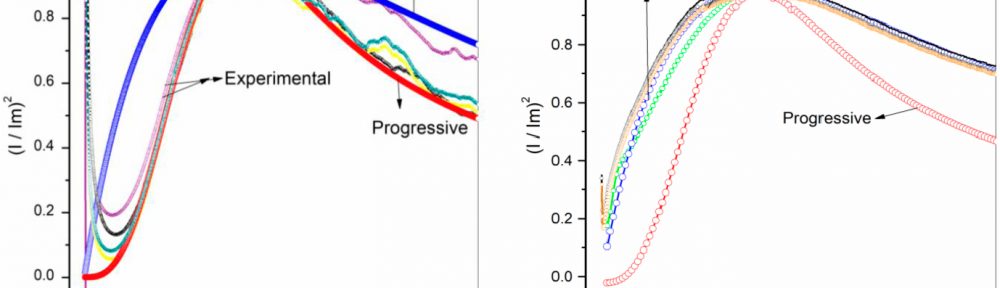

Investigation of nucleation mechanism and surface morphology of the crystallites in zinc-cobalt alloy coating

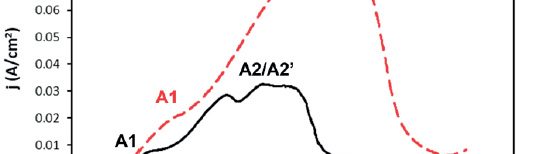

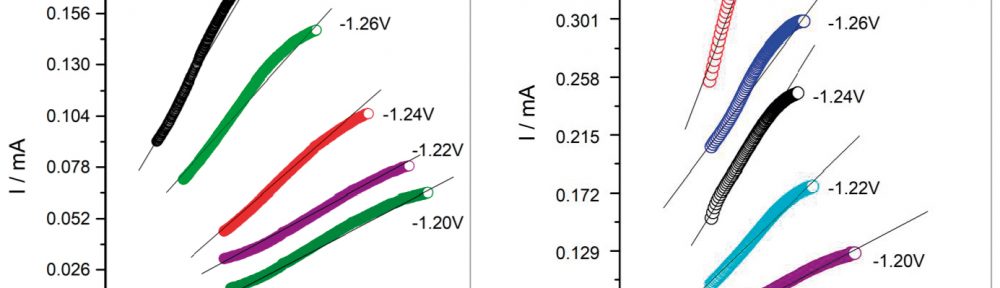

In present investigation, a new brightener was synthesized by condensation of 3, 4, 5-Trimethoxy benzaldehyde and Glycine (TG). Hull cell experiments were conducted to optimize the plating bath components and operating parameters. To examine the influence of TG on nucleation mechanism of Zn-Co alloy electrodeposition, cyclic voltammetry and chronoamperometry study was carried out. Schariffker and Hills model was used to analyze current transients, which in presence of TG confirmed instantaneous nucleation. Corrosion studies were done using potentiodynamic polarization and electrochemical impedance spectroscopic technique, in 3.5 wt. % NaCl for bright and dull zinc-cobalt alloy coatings. Phase structure, surface morphology and brightness of the deposit were characterized by X-ray diffraction analysis, scanning electron microscopy and reflectance studies. These studies revealed the role of TG in modifying the nucleation mechanism and surface morphology of zinc-cobalt alloy crystallites and thereby producing a bright corrosion resistant Zn-Co alloy coating on mild steel substrate.

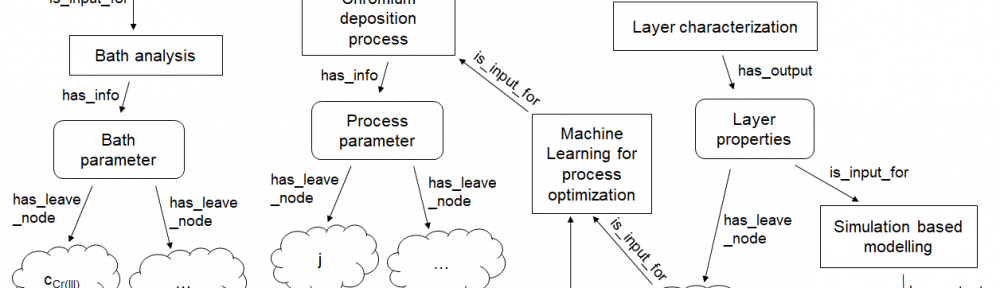

The need for digitalisation in electroplating - How digital approaches can help to optimize the electrodeposition of chromium from trivalent electrolytes

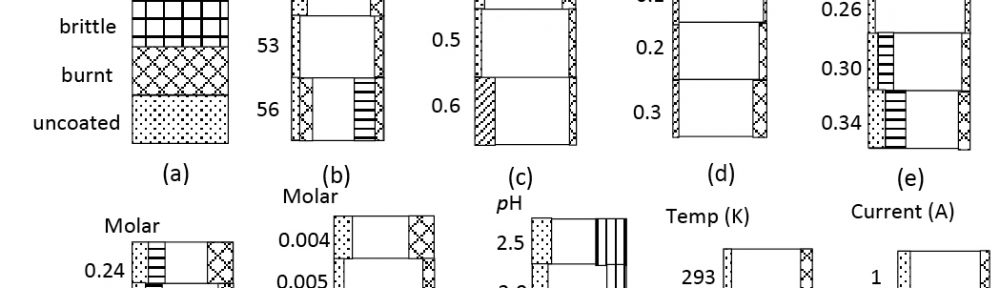

In order to make material design processes more efficient in the future, the underlying multidimensional process parameter spaces must be systematically explored using digitalisation techniques such as machine learning (ML) and digital simulation. In this paper we shortly review essential concepts for the digitalisation of electrodeposition processes with a special focus on chromium plating from trivalent electrolytes.

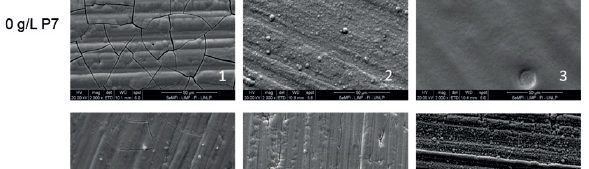

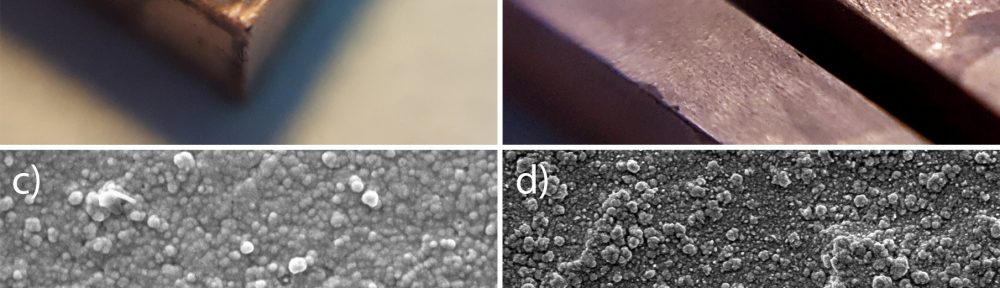

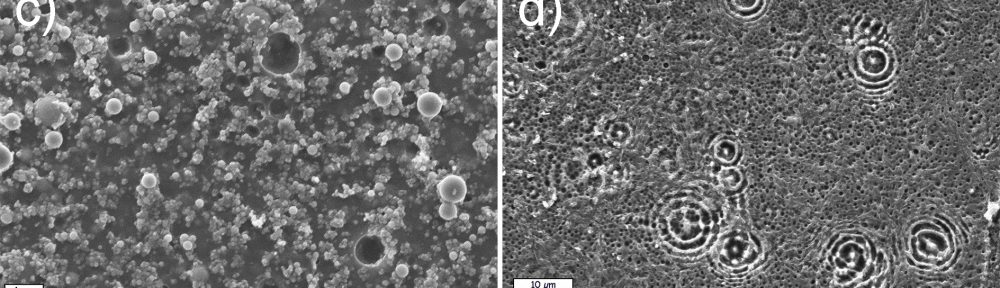

Influence of wet surface pretreatment on the electroless metallization of stereolithography resins

In the present paper, the influence of different wet pretreatment routes on the final quality of electroless layers plated on stereolithography resins is investigated. Two pretreatment methods, acidic and alkaline, are employed. Acidic etching is unable to provide acceptable results in terms of surface quality. On the contrary, alkaline etching guarantees a bright copper surface coupled with a level of adhesion high enough to pass a standard peel test. ATR FT-IR is employed to investigate the chemical reactions occurring on the resins during the pretreatment, evidencing a major role of the ester hydrolysis process on the depolymerization of the material and on the formation of new functional groups on the surface. Resin hydrolysis is linked with increase in surface roughness and wettability, parameters that strongly determine final metal adhesion. The combination of ATR FT-IT, contact angle and roughness measurement constitutes a possible combined methodology to follow the evolution of surface pretreatment on different stereolithography resins.