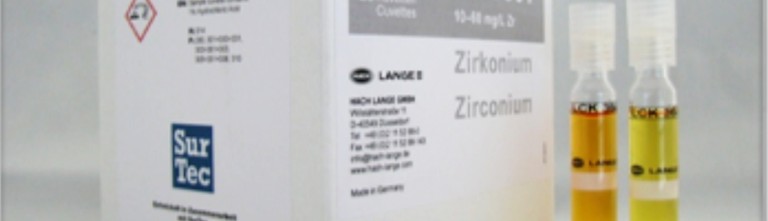

NickFor post treating anodising layers on aluminium, typically two different technologies are applied, the hot water sealing at 96-100 °C and the cold sealing using reactive salts to plug the pores of the anodic coating. Both applications show major disadvantages. Whereas the hot water sealing is extremely energy consuming due to the mandatory hot process temperature, the low temperature sealing processes typically apply nickel compounds being harmful to the environment. Nickel salts are toxic and carcinogenetic, having irreversible effects on the human body and health. Furthermore, nickel containing waste waters are difficult to treat, especially when also aluminium is present [1]. New nickel-free technologies have been developed accordingly, enabling a low temperature application yielding in major energy savings. The deposition of antisoluble compounds in the pores of the anodizing layer leads to best stability and corrosion protection, exceeding the performance of hot water sealing. The new process solutions as being non-toxic are less risky to store and to handle, assisting the safety at work. Implementing a new photometrical method for analysing the ingredients, process stability and production quality can be improved [2]. In some cases, the pH-resistance of the anodised surface can be enhanced, extending the application field of anodised aluminium. Moreover, the waste water treatment of the rinses is carried out at pH 9–10, hence, can be done mutually with aluminium containing effluents.

Post Treatment of Anodising Layers / Nickel- and Cobalt free Alternatives Working at Ambient Temperatures

NickFor post treating anodising layers on aluminium, typically two different technologies are applied, the hot water sealing at 96-100 °C and the cold sealing using reactive salts to plug the pores of the anodic coating. Both applications show major disadvantages. Whereas the hot water sealing is extremely energy consuming due to the mandatory hot process temperature, the low temperature sealing processes typically apply nickel compounds being harmful to the environment. Nickel salts are toxic and carcinogenetic, having irreversible effects on the human body and health. Furthermore, nickel containing waste waters are difficult to treat, especially when also aluminium is present [1]. New nickel-free technologies have been developed accordingly, enabling a low temperature application yielding in major energy savings. The deposition of antisoluble compounds in the pores of the anodizing layer leads to best stability and corrosion protection, exceeding the performance of hot water sealing. The new process solutions as being non-toxic are less risky to store and to handle, assisting the safety at work. Implementing a new photometrical method for analysing the ingredients, process stability and production quality can be improved [2]. In some cases, the pH-resistance of the anodised surface can be enhanced, extending the application field of anodised aluminium. Moreover, the waste water treatment of the rinses is carried out at pH 9–10, hence, can be done mutually with aluminium containing effluents.