While there are a large number of written documents on nickel as a coating, there are very few dealing with nickel electroforming. This technology is an important consumer of nickel – about 5,000 tons per year worldwide – used to manufacture a wide range of articles (it is a manufacturing process, not a coating process). It is indeed the ONLY process that can produce certain very important products that are very often used in society. Most people are not aware of the process and its importance. It is a process that is indispensable for the production of compact audio discs and digital visual discs. Since the annual production of these items is estimated at about 4.000,000,000, you can see how important it is for our lifestyle today. Another very large application is the mass production of holograms.

Tag Archives: electroforming

Electroplating of Nickel in Grooves Under the Influence of Low and Medium Frequency Ultrasound

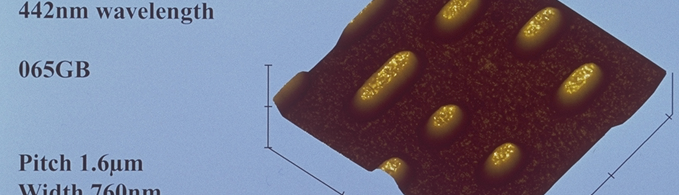

The effect of ultrasonics on filling properties has been studied by Ni electroplating from a sulphamate electrolyte in high aspect ratio grooves. Experiments were carried out with two different modes of ultrasound: a) 25 kHz ultrasound with an effect of 225 W directed perpendicular to the substrate surface; b) ultrasonic standing waves of 100 kHz and 400 kHz parallel to the substrate surface. It was found that both methods improve filling in grooves that are between 0.35 and 1 mm wide with aspect ratios between 0.6 and 3, compared to electroplating with conventional agitation. Under the investigated conditions, the 400 kHz standing wave parallel to the surface was most efficient to improve filling of grooves.