A few days ago we had introduced to you Dr. Saeid Kakooei as an new member of our Advisory Board. Today I have the great pleasure to welcome Prof. Isabel Díaz Tang too. Continue reading…

Yearly Archives: 2015

Dr. Saeid Kakooei - New member of the Advisory Board

Today we want to introduce Dr. Saeid Kakooei to you. He is a new member of our Advisory Board. Working as a lecturer he is teaching Corrosion Engineering, Engineering Materials and Thermodynamic courses in Universiti Teknologi Petronas (UTP) to Undergraduate students of Mechanical Engineering Department, he has a lot of experience. Continue reading…

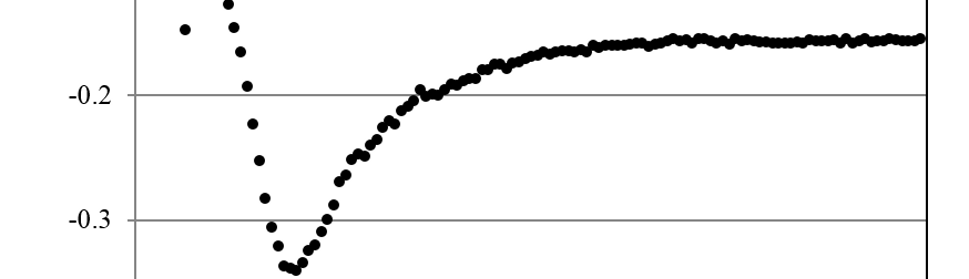

Malonic Acid as Corrosion Inhibitor for Carbon Steel in 1 M Hydrochloric Acid Solutions

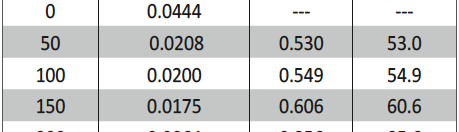

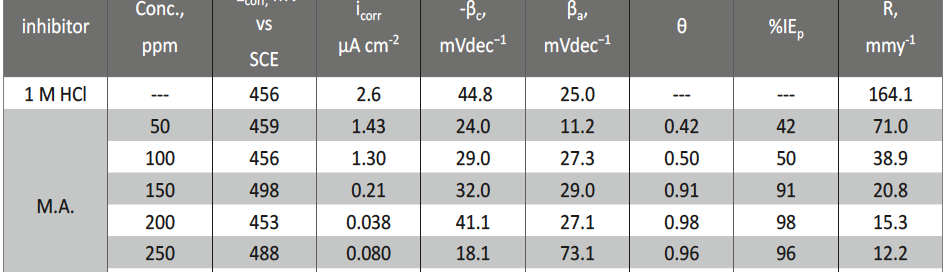

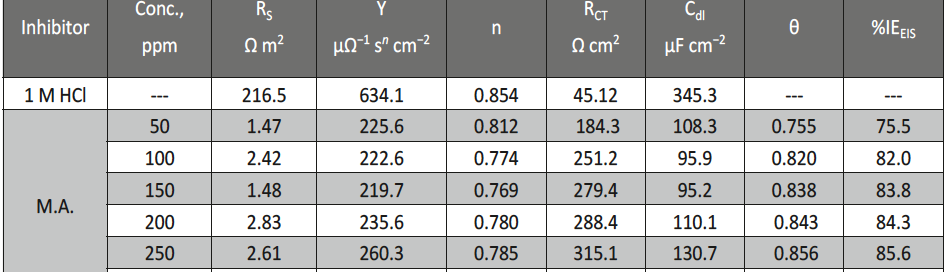

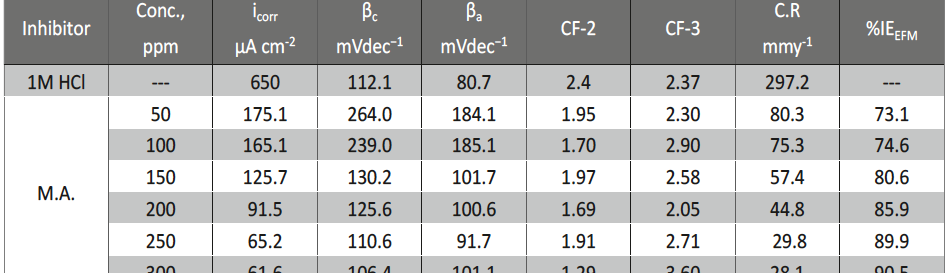

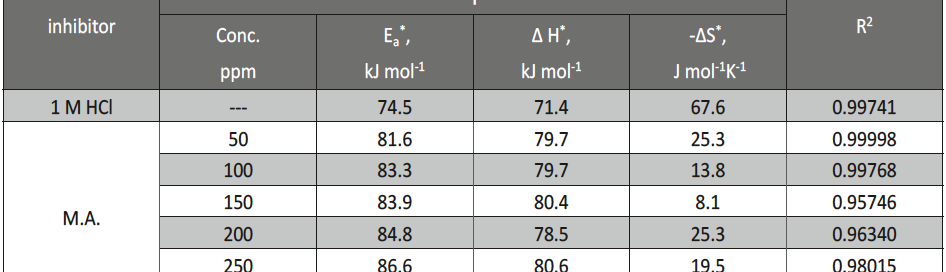

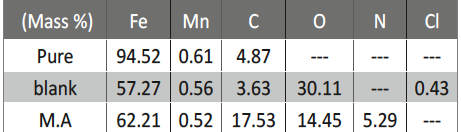

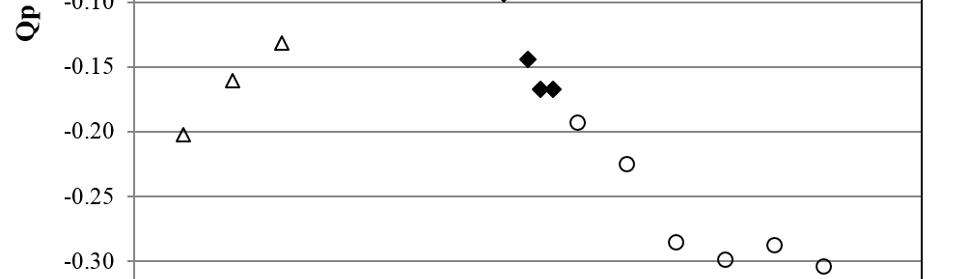

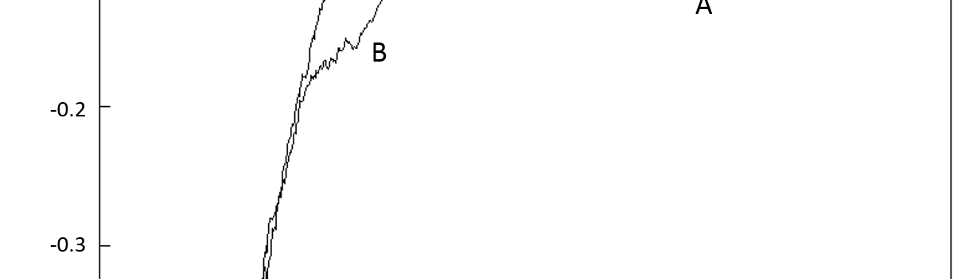

The protection effect of malonic acid on carbon steel corrosion was studied in aerated stagnant 1M HCl solutions at 250C. Measurements were conducted under different experimental conditions using weight loss, Tafel polarization, electrochemical impedance spectroscopy (EIS) and electrochemical frequency modulation (EFM) techniques. malonic acid was found to be good inhibitor of carbon steel corrosion in1 M HCl. The adsorption of this inhibitor is found to obey the Langmuir adsorption isotherm. The calculated activation energies proposed that the inhibitor molecules being physically adsorbed onto the metal surface. Polarization data revealed that this compound behave as mixed type inhibitor.

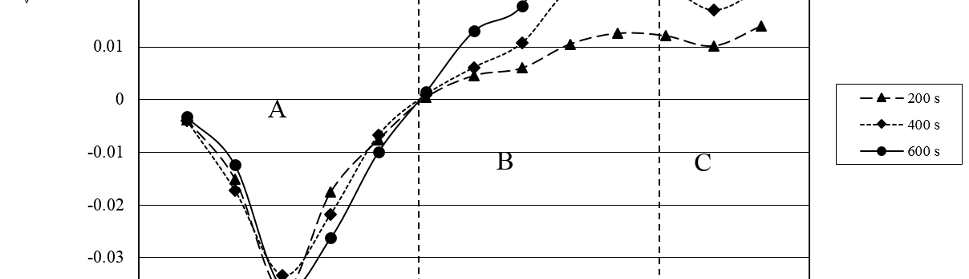

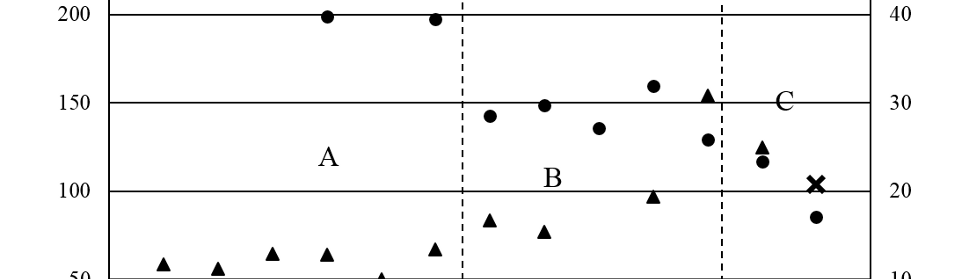

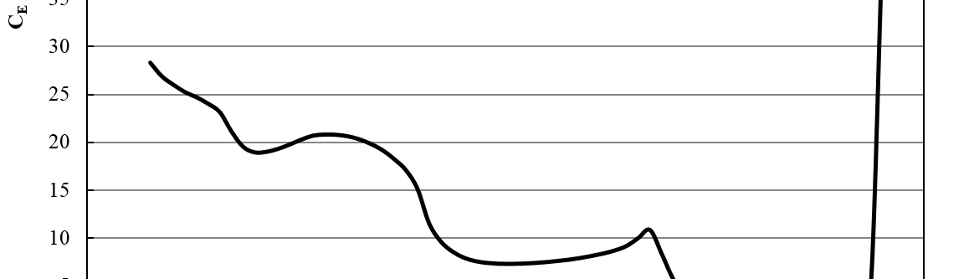

Square Wave Pulsating Overpotential Treatment of Chromic Acid Solution

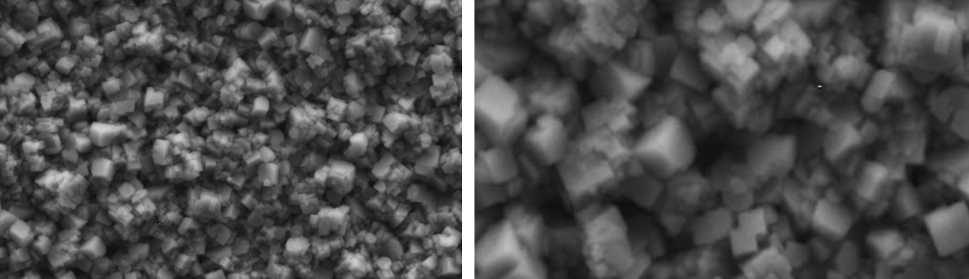

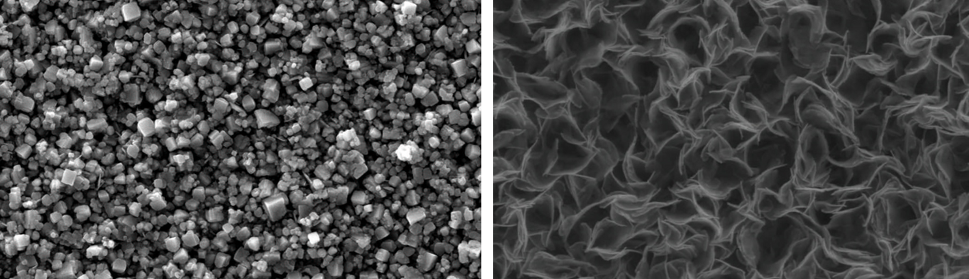

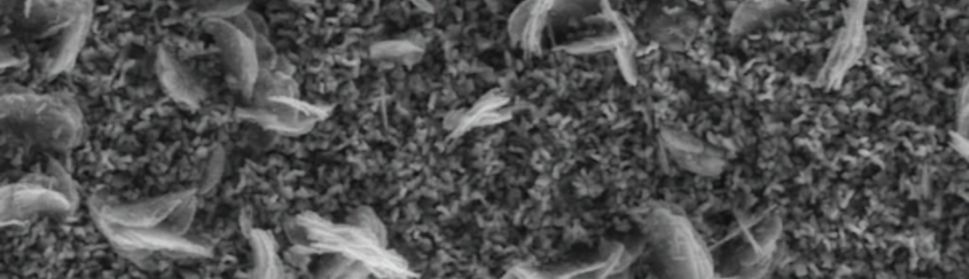

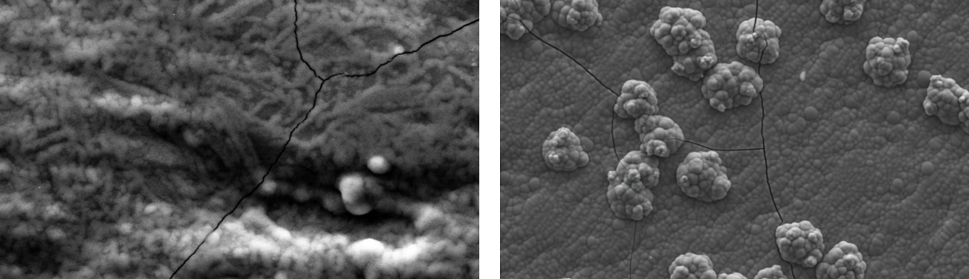

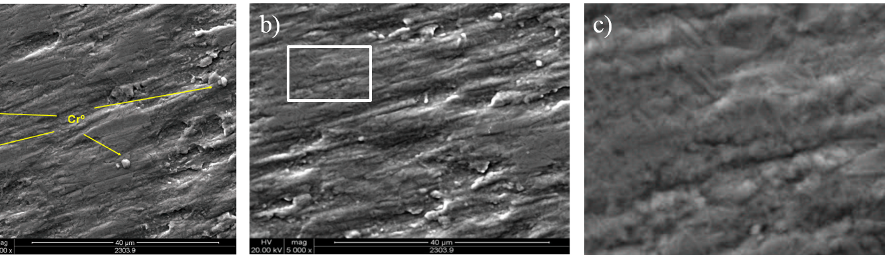

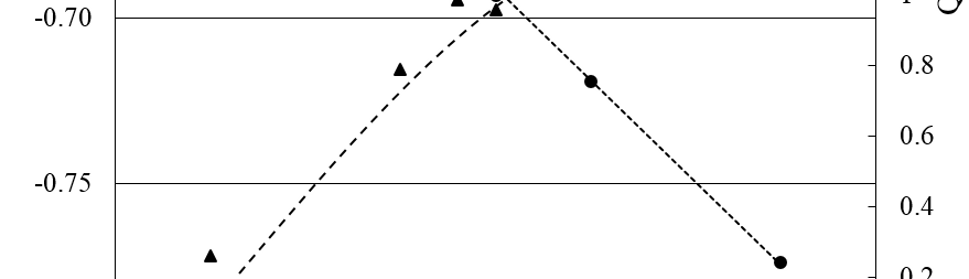

Systematic investigation of square wave pulsating overpotential (SWPO) treatment of a chromic acid solution is presented. Some preliminary potentiodynamic scans, potentiostatic deposits, potential steps and capacitance vs. potential curves were measured in order to establish the practical range of the SWPO signal parameters. The results show that properly adjusting the electrochemical parameters of the cyclic alternating potential perturbation it is possible to obtain cracked or crack free metallic chromium or chromium oxide/hydroxide mixed coatings. The different deposit morphologies were characterized through scanning electron microscopy and their chemical composition and micro hardness was measured. Some insight into the possible mechanisms of coating growth under this potential cycling treatment is given.

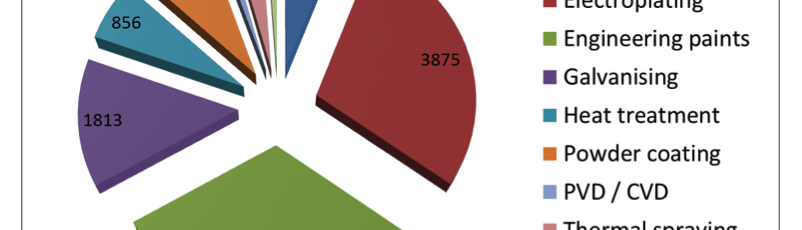

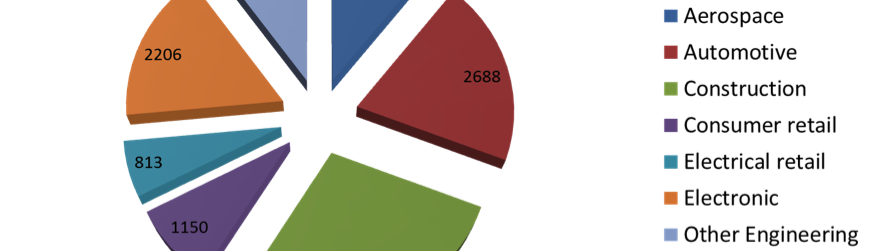

Overview of the UK Surface engineering sector

Surface engineering is a sub-discipline of materials science and covers a multitude of processes such as electroplating, anodising, electro-polishing, heat treatment processes, physical vapour deposition and the like. The term surface engineering was promoted by, amongst others, Professor Tom Bell of the University of Birmingham defining it as “the design of surface and substrate together as a functionally graded system to give a cost-effective performance enhancement of which neither is capable on its own”. Imagine a world without cars, aeroplanes, trains, computers, mobile phones, medical implants, buildings, electronics, in fact virtually no manufactured products – that’s a world without surface engineering. Thus, the application of surface engineering is vital to the success of almost every commercial and industrial product: from aero engines to aeroplanes, from iPods to surgical implants and from razor blades to racing cars.